The efficiency with which the water is drained from the deck is directly affected by the location and cleanliness of the scuppers on bridges with solid railings or parapets. Bridges that have steel guardrail with tubular backup on steel posts usually are designed to allow drainage to run directly over the sides of the bridge. This is especially true on many reinforced concrete slab and prestressed concrete box beam bridges. The drainage is usually efficient in draining quickly over the sides of the bridge, but in doing so also allows the sides and bottom corners of the bridges to become saturated with salt-laden moisture. As a result, the chlorides penetrate the concrete and attack the reinforcing steel on concrete slabs and the prestressing strands on box beams. As the reinforcing steel or the prestressing strands corrode, they expand slightly causing the concrete to spall off. This spalling progresses back under the deck and eventually cause structural damage. A simple solution to the edges of bridges with over-the-side drainage involves the use of a galvanized steel (or stainless steel) drip strip attached to the top edge or embedded into the sides of the bridges. This steel drip strip causes drainage to drop directly down to the ground instead of running down and under the sides of the bridge and thus protects the sides from deterioration. Steel drip strips are difficult to install with maintenance forces unless being added when the bridge is being overlaid with asphalt or concrete. The sides, however, can be protected with silane/siloxane or epoxy/urethane sealers and extended about 18" under the bottom side. This is action is strongly recommended to extend the life of these bridges.

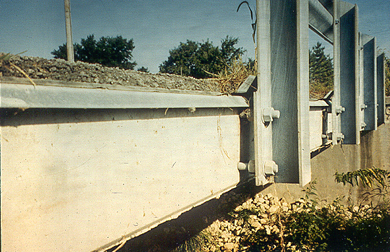

Use of drip strip along upper edge of deck, to minimize water flow to the underside.